Advanced Sterilization Solutions in Delhi

As a leading Autoclave manufacturer, we support the medical and biological research sectors of Delhi. Serving the vast NCR industrial belt from Okhla to Bawana, we provide 24-hour calibration support for government R&D labs and private manufacturing units. Our service engineers are active in Connaught Place, Okhla Industrial Area, Nehru Place, and Dwarka, providing installation and validation services that comply with international safety standards.

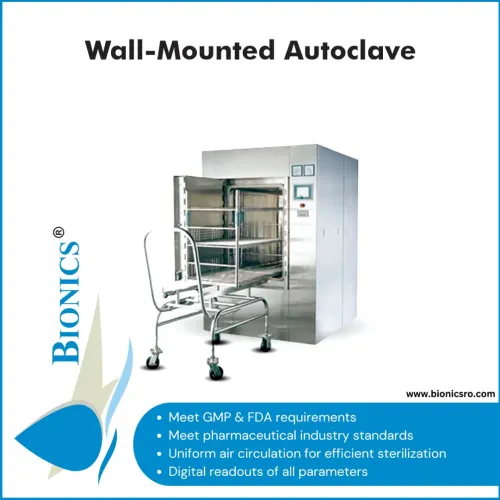

Autoclave Machine Manufacturers in Delhi offers the most dependable and best performing sterilizers in the industry. Autoclave Machine Manufacturing services multiple industries and provides the most dependable and energy efficient sterilizers available. Every autoclave is crafted so that sterilization is achieved at the maximal level. Engineering and Advanced Manufacturing techniques from seasoned professionals ensure that maximum efficiency is achieved over long periods. Bionics Engineering offers the most value in the industry from the methods developed that ensure customized solutions.

Autoclave Machines in Delhi are available in different forms and configurations so that different industries and markets can be serviced. This includes hospitals, research facilities, pharmaceuticals, dental, biotechnologies, agriculture, food processing, and educational sectors. Every design is created so that users have the best experience and the ease of installation. This allows customers to select the best fitting model, including optional composite accessories, automation, and custom configurations to suit their operational and regulatory requirements.

Certified Autoclave Machine Suppliers in Delhi

Bionics Consortium is one of the trusted Autoclave Machines Suppliers in Delhi. It has built a reliable reputation in the market. Autoclave sterilization products are ISO, GMP and CE Certified, International Safety Standards and International Quality Standards. Support offered by Bionics Consortium is complete as customers are offered a series of autoclaves manufactured to satisfy users in circumstances where sterile, hygienic, and processed controlled state are vital.

Support of our autoclaves extends to products which are general purpose and those which are specially engineered. There are benchtop compact autoclaves and big industrial autoclaves. Each of the available products has been tailored to provide opportunities to correspond to the specific operational environment and the work load.

- Uniform temperature distribution

- Accurate pressure control

- Efficient air removal

- Consistent sterilization cycles

We shall help you in designing and manufacturing an autoclave sterilizer that meets your specific needs. All of our models shall offer you a range of different features and capabilities. Some of the features that you may opt for include automation, validation, data logging, remote monitoring, and safety.

Autoclave sterilizing machine is commonly known as steam sterilizes as it is an enclosed pressure system built for sterilizing tools, substances and wastes with superheated steam, under pressure.

Autoclaves are effective and kill all microorganisms including bacteria, viruses, fungi and spores, making them vital in sterile settings such as hospitals, labs and pharmaceutical production.

Standard sterilizing conditions:

- Temperature - in between 121 and 134 °C

- Pressure - 15 to 30 psi

- Time - 15 to 20 min varying from the load and material

This steam penetration is to ensure the complete and effective sterilization.

What is an Autoclave Sterilization Machine?

Differentiation in the types of autoclaves euthanizing is gone with regards to the sterilization and design. This mostly concerns the way the air has been removed from the chamber to allow steam penetration.

By sterilization technology classes:

- Class N (Gravity Displacement):

For unwrapped, solid and simple instruments. The steam coming in is sufficiently displaced. Autoclaves are often found in basic laboratory settings.

- Class S (Steam Flush / Pulse):

For steam-sterilization processes, this class uses steam pulses to remove air trapped inside packaging materials more quickly. It is suited to steam-sterilizing wrapped instruments, textiles, and certain hollow items.

- Class B (Pre-Vacuum):

This class is the most sophisticated and operates by using a vacuum pump to remove air from the chamber completely with a steam injection. It is also best for sterilizing the most difficult and complex hollow porous instruments including dental instruments as it offers the best level of sterilization.

By Physical Design / Loading Type

- Vertical (Top-Loading): Best for laboratories, liquids, culture media and glassware.

- Horizontal: Best suited for large and bulky loads.

- Benchtop / Tabletop: Best compact and space-saving option for clinics and dental practices.

- Large Capacity / Industrial: Ideal for high-volume sterilization intended for industrial places.

What is the Working Principle of an Autoclave Machine – Dependable Autoclave Machine Dealers in Delhi

Dependable Autoclave Machine Dealers in Delhi provide most laboratory and clinical autoclaves that use steam under pressure to achieve sterilization.

Stages of the Sterilization Process

- Purge Phase:

Removal of air from the chamber by means of gravity displacement, steam flush or vacuum, this must be done to allow the steam to penetrate more efficiently.

- Exposure Phase:

Steam is injected into the chamber and the required temperature and pressure must be maintained for a set time to kill off the microorganisms.

- Exhaust Phase:

The pressure is released in a controlled manner through the valves and the chamber is returned to ambient conditions safely and under control.

This controlled cycle guarantees successful sterilization, reliability, and the safety of the users.

Temperature, Pressure and Time, Autoclave

- Operating Temperature: 121C 134C

- Operating Pressure: 15 30 psi

- Sterilization Time: 3, 60 minutes (depending on the load, material and the type of cycle).

Medical accessories have higher demands and necessitate shorter cycle times, on the other hand, wrapped goods, fabrics, and heavier items are subjected to longer times of exposure.

- Vessel / Chamber: Constructed of SS 316 or SS 304 stainless steel to prevent corrosion.

- Control System: Touchscreen control, based on microprocessor or PLC.

- Thermostatic Steam Tap: Eliminates the air and condensate.

- Safety Valve: Prevents pressure runaway scenario.

- Waste-Water Cooling System: Cools and discharges steam and condensate.

Industrial Applications of Autoclave Machine: Autoclave Exporters in Delhi you can trust

The industries that need quality, precision and consistency in their measurements are the ones that have to use Autoclaves: Healthcare and Bioscience: Surgical tools, lab glassware, culture media, bio-waste. Autoclave Machine Exporters in Delhi are reliable and offer the best sterilizers to your nearest faculty.

- Food/Beverage: Sterilization of packaged foods, cans and their containers.

- Medicines: Sterilization of containers, devices and the formulation of their recipes.

- Biotechnology: Fermentation devices, cells and other contaminated waste.

- Material Processing: Composite curing, laminated glass, aerospace parts.

- Vulcanization of rubber: Manufacturing.

- Agriculture: Tissue sterilization of soil, seeds and plant tissue.

Advantages of Autoclave Sterilizers

Autoclaves Bionics Consortium has several operational and business advantages are :

- Efficient sterilization

- Operational and maintenance simplicity

- Energy efficiency

- LongServiced life

- ISO, CE, and GMP certification

- Diverse range of models and customized

Key features of autoclave machines

- Sterilization of materials and products

- Operating at 121 ° and 134 °

- Effective air removal through gravity, steam flush or vacuum.

- Real-time monitoring and optional data logging.

- Autoclave Sterilizers are designed for hospitals, laboratories, dental clinics, and other industrial facilities.

Autoclave Machine Price in Delhi

Autoclave Machine Price in Delhi depends on;

- Type and capacity of autoclave

- Degree of automation

- Specific requirements of the application

- Available accessories and validation requirements

- The right pilot plant will allow optimal operation, regulation compliance and the best overall investment return over time.

Ready to Upgrade Your Sterilization Process?

Contact the bionics consortium to discuss your requirements. Get a free consultation regarding selection of the right autoclave as per your business requirement.