High-Precision Thermal Engineering for Mohali Labs

Bionics Scientific is a trusted name in the manufacturing of Laboratory Oven, designed specifically for the thermal research needs of Mohali. We provide tailored laboratory solutions for research and industrial applications across Mohali. We ensure rapid delivery and on-site calibration across major industrial zones to maintain zero downtime for your high-temperature processes.

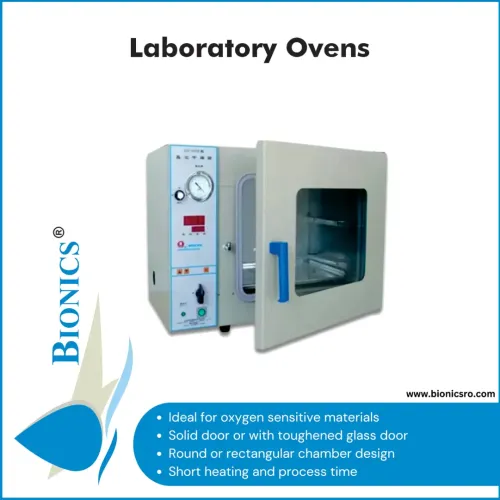

Laboratory Ovens Manufacturers in Mohali offer sophisticated laboratory ovens for sample drying and heating for chemical reactions, and laboratory ovens used for polymerization, curing, sterilization and heating are essential tools in scientific, industrial, and research laboratories when accuracy and safety are of utmost importance.

However, Laboratory Ovens in Mohali have electrical, fire, and burn risks if not designed properly. Ovens that are not intrinsically safe and specially designed for heating volatile organic solvents, flammable liquids, and shock sensitive materials are risky. Therefore, choosing a laboratory oven manufacturer and supplier should be done very carefully.

Best Laboratory Oven Suppliers in Mohali

Bionics Consortium is one of the Best Laboratory Oven Suppliers in Mohali for many years for various sectors because of their reliable and high quality heating products and excellent service.

Their laboratory ovens are in use for:

- Biomedical and research labs

- Pharmaceutical and chemical sectors

- Textile, rubber and food industry

- Coal, paint and material testing sectors

The company’s engineers have incorporated advanced features like microprocessor controllers, digital timers, chart recorders, printers, mobile wheels, and over-temperature protection. All products are designed for safe operation and high temperature accuracy, and comply with safety and quality standards worldwide.

Via customer support, assistance, and team members, clients are able to address and fulfill their pricing, customization, manufacturing, or supply queries and needs.

What are Laboratory Ovens?

Laboratory ovens are heating equipment that operates at consistent and steady temperatures between 100 and 300 °C, but can also reach higher than that.

These ovens are often used for:

- Baking and evaporating samples

- Sterilization and dry heat

- Scientific research at high temperatures

- Curing and heat treatment

- Laboratory ovens are used in laboratories like chemistry, biology, material science, electronics, forensics, and clinical research, where repeatability, reliability, and accuracy are important.

Different laboratory tasks vary in their needs, and in their types of ovens. Common types of laboratory ovens are:

Laboratory Ovens

These ovens dry heat-sensitive materials without oxidation. Specific systems are used to ensure a safe evaporation of water vapor and to protect the environment.

- High-Temperature Ovens

These ovens are commonly used in the ceramics and pottery industries and are designed to reach temperatures of 400 °C to 500 °C. They also have a high insulation to survive heavier temperatures and voltage safely. They are used in the pottery and ceramics industry.

- Forced Air Convection Ovens

They use fans to move the hot air around making them quicker to heat and also distribute the heat more evenly. These are great for consistent drying but can lead to over-drying for more sensitive samples.

- Gravity Convection Ovens

These ovens rely on the natural spilling of hot air and are more energy efficient than the others. This also makes them a better choice for applications where gentle heating is more desirable.

What Laboratory Ovens Do - Best Laboratory Oven Dealers in Mohali

Laboratory ovens heat a specific space using inner heating elements and a controlled flow of air, which is then located to the outside environment. Different model ovens heat space differently.

By working with the Best Laboratory Oven Dealers in Mohali, you can obtain the use of temperature regulated laboratories that are able to facilitate essential activities such as:

- Curing

This is the method of using heat to change the state of specific materials, changing either the physical or chemical properties, and is commonly used for rubber materials, plastics, coatings, adhesives, paints, and other proprietary materials.

- Drying

This is the method of taking moisture out of samples which is paramount in pharmaceutical laboratories, biological laboratories, and environmental laboratories.

- Annealing Heat

This is a controlled heating followed by a slow cooling where heat is removed for the purpose of relieving internal stresses which occur in metals, glass, and electronic assemblies.

Why Selecting Bionics Consortium – Reputable Laboratory Oven Exporters in Mohali

Bionics Consortium is one of the Most Reputable Laboratory Oven Exporters in Mohali with a wide range of products that includes:

- Commercial ovens

- Thermal convection ovens

- Desiccator ovens

- Tailored laboratory heating products

Their engineering department collaborates with customers to provide customized laboratory ovens designed to suit specific applications with affordable solutions. With top-notch engineering, contemporary industrial production, and comprehensive quality control, these products provide peace of mind with regard to reliability and safety for extended years.

The Temperature Range of Laboratory Ovens

The operating temperature of a laboratory oven is dictated by the specific model, the size, and the intended purpose.

Basic laboratory ovens: Up to 300°C (recommended for drying and moisture removal)

Industrial, high-temperature, and special-purpose ovens: 600°C – 700°C or more for processes such as annealing, sintering, and other advanced material processing

Available Sizes and Capacities of Laboratory Ovens

Laboratory ovens come in different capacities:

- From 30 liters to more than 900 liters

- The smaller ones are designed to be bench-mounted.

- The larger-sized ovens are often floor-mounted because of their size and heaviness.

- This diversity enables laboratories to select ovens that fit their available workspace and workload needs.

Are Lab Dryers Capable of Material Drying?

Yes, lab dryers can serve as drying ovens as long as there is proper venting. For powder and lighter materials, natural convection ovens are preferred since the sample can become disturbed. Adding moisture exhaust vent fans can increase drying efficiency.

Important Considerations When Purchasing a Laboratory Oven

Think about the following before purchasing a laboratory oven.

- The total volume and dimensions of the chamber

- The highest temperature that can be reached

- Consistency and precision levels of temperature

- The type of sample materials (solid, liquid, or a mixture of solvent)

- Identification and control of safety risks such as explosion venting, and control of airflow

How Household Ovens Differ from Laboratory Ovens

Compared to conventional ovens which are found at home or in food premises, laboratory ovens are built to be tougher and are more accurate. They are built with an interior and exterior of stainless steel, are designed to be continuously used, and have to be built to the safety regulations of the laboratory.

Are Laboratory Ovens Suitable for Heating Samples with Solvents?

Yes, but only for laboratory ovens that are designed to contain the vapors from solvents used. This type of oven is placed under the EN 1539 safety standard and is equipped with explosion venting, and controlled airflow systems for the safe handling of combustible gases.

Get the Correct Laboratory Oven for Your Needs

Selecting the appropriate laboratory oven is a decision that impacts more than just the bottom line. The right construction, temperature regulation, and operational safety enhancements will make laboratory ovens a source for reproducibility and dependable results.

Searching for the Best Laboratory Ovens in Mohali?

Work with Bionics Consortium for state-of-the-art, dependable, and tailor-made laboratory oven offerings.

- Heating accuracy | Global safety compliance | Personalized designs.

- Reach out today to go over your laboratory oven specifications with us.