High-Precision Thermal Engineering for Uttar Pradesh Labs

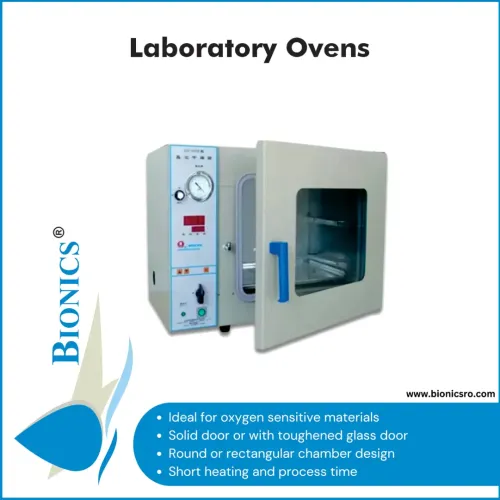

Bionics Scientific is a trusted name in the manufacturing of Vacuum Tray Dryer, designed specifically for the thermal research needs of Uttar Pradesh. We provide tailored laboratory solutions for research and industrial applications across Uttar Pradesh. We ensure rapid delivery and on-site calibration across Noida, Lucknow, Kanpur, and Agra to maintain zero downtime for your high-temperature processes.

Drying is a key determinant of total production efficiency particularly in industry where the quality of end products, thermal stability and regulatory conformity are key determinants. Vacuum Tray Dryer in Uttar Pradesh or (VTD) is a special type of drying equipment that is used to dry out the materials that are sensitive to heat and have a tendency to take up moisture in case the reduction of pressure is done. It allows low temperatures of drying to provide controlled, consistent, and non-damaging drying.

The technology is widely applicable in the pharmaceutical, chemical, food and R&D industries where products require preservation in terms of their physical and chemical properties.

Bionics Consortium is one of the most reputable Vacuum Tray Dryer Manufacturers in Uttar Pradesh and specializes in providing strong, stable, and regulatory drying tools with efficient heat transfer and balanced performance in the region. This manual gives an in-depth review of the Vacuum Tray Dryers and their working principle, design aspects, uses and benefits of such machines to enable the purchasers to make good decisions.

What Is a Vacuum Tray Dryer - Top Vacuum Tray Dryer Suppliers in Uttar Pradesh

Vacuum Tray Dryer is a batch-type drying device whereby the material is dried or the solvents evaporated by keeping the device under vacuum conditions. The pressure within the closed drying tower is decreased to a great extent which means that the boiling point of liquids is decreased significantly resulting in drying at much lower temperatures compared to dryers in the atmosphere.

Vacuum Tray Dryers are suitable to:

- Pharmaceutical products that are heat sensitive

- Chemical compounds which are solvents

- Sensitive and perishable goods

Top Vacuum Tray Dryer Suppliers in Uttar Pradesh caters to Pharmaceutical manufacturers, chemical processors, food industries and research laboratories who require a reliable contamination-free drying.

Working Principle of a Vacuum Tray Dryer

A Vacuum Tray Dryer works on the principle of evaporation under vacuum and conductive heat transfer, which means that it is possible to control the conditions of drying accurately.

Step-by-Step Drying Process:

- Loading: Wet material is uniformly covered on trays in order to have even drying.

- Sealing: Trays are put on the hot shelves of the vacuum chamber.

- Vacuum Application: A vacuum pump removes the air and lowers the pressure in the inside.

- Heating & Evaporation: Low temperatures are required where the moisture or solvents are evaporated out under controlled heat.

- Vapor Removal: Solvent recovery is done by constantly removing vapors which are normally condensed.

It is an ideal process in terms of pharmaceutical and specialty chemicals since it reduces thermal stress.

Scientific Basis: Why Vacuum Drying Is Effective

Thermodynamically, the vacuum drying reduces the latent heat of vaporization and thus liquids can be easily evaporated at lower temperatures.

For example:

- The boiling point at atmospheric pressure is 100OC.

- Boiling may be done under vacuum with temperatures of 40-50OC or lower.

This strength is imperative to:

- Thermally unstable APIs

- Bioactive compounds and enzymes

- Herbal and nutraceutical extract

Key Components & Construction - Trusted Vacuum Tray Dryer Exporters in Uttar Pradesh

Vacuum Tray Dryers are designed to be durable, hygienic, and provide long term performance.

Major Components:

- Drying Chamber: It is made out of SS 304 or SS 316, which are resistant to corrosion and maintain vacuum integrity.

- Trays and Shelves: Flat trays stacked on hot shelves to have a uniform conductive heat transfer.

- Heating System: Steam, electrical or hot-water heating.

- Vacuum System: Vacuum pumps are high efficient and have gauges and control valves.

- Condenser: Solvent recovery as well as safeguarding the vacuum pump.

- Control Panel: PLC or digital controls so that it can be monitored accurately.

There are manufacturers who are considered as the major Vacuum Tray Dryers Exporters in Uttar Pradesh and guarantee that the global quality and safety standards are met.

Design Engineering Considerations - Best Vacuum Tray Dryer Dealers in Uttar Pradesh

In addition to the simple construction, the efficiency of dryers is strongly positional on the accuracy of design:

- Effective heat transfer was achieved by providing tray thickness and flatness.

- Adequate inter-tray space in order to provide proper evacuation of vapor.

- Surface finishes of good quality that would facilitate cleaning and avoid sticking of products.

Lack of design may lead to non-uniform drying and batch irregularity thus the reason why dependable Vacuum Tray Dryer Dealers in Uttar Pradesh are so keen on engineering rather than the initial low costs.

Typical Technical Specifications

Applications have different specifications, although the most common are:

- Operating Temperature: 80–90°C

- Vacuum Level: Up to 760 mmHg

- Construction Material: SS 304 / SS 316 / SS 316L

- Batch Capacity: Laboratory to industrial scale

- Heating Methods: Steam, electric, hot water

- Controls: PLC, digital, or manual

Applications of Vacuum Tray Dryer

The Vacuum Tray Dryers can be widely used as it is versatile and gentle in its drying effect.

Key Applications:

- Pharmaceuticals: APIs, intermediates, granules, heat sensitive drugs.

- Chemicals: Specialty chemicals, catalysts, poisonous substances.

- Food & Herbal: nutraceutical powders, enzymes, Herbal extracts.

- Cosmetics: Sensitive cosmetic ingredients.

- R&D Laboratories: Formulation development and production on pilot-scale.

Advantages of Vacuum Tray Dryer

Vacuum Tray Dryers have several advantages over the traditional drying technique:

- Low temperature drying maintains the potency of the product

- Keeps off oxidation and thermal degradation

- Even drying of the trays

- Allows the recovery and re-use of solvents

- Sensitive material energy efficient

- Closed system reduces contamination

These benefits present Vacuum Tray Dryers as a choice of many industries in the world.

Vacuum Tray Dryer vs Other Drying Systems

|

Dryer Type

|

Key Characteristics

|

|

Tray Dryer

|

Atmospheric drying, higher temperatures

|

|

Vacuum Tray Dryer

|

Low-temperature drying for sensitive materials

|

|

Spray Dryer

|

Continuous drying, liquid-to-powder

|

|

Fluid Bed Dryer

|

Rapid drying for granules

|

|

Rotary Dryer

|

Bulk drying for non-sensitive materials

|

Vacuum drying is the best choice when stability and quality of products are of more importance than speed of drying.

Compliance, Safety & Quality Standards

It is a dryer that is constructed to satisfy stringent industry requirements:

- GMP and cGMP compliance

- FDA-approved materials (SS 316L)

- Vacuum construction that is leak proof.

- Convenience in cleaning and validity of resourcefulness.

- Temperature limiters and safety valves.

Automation & Modern Control Systems

Advanced Vacuum Tray Dryers are fitted with:

- Temperature and vacuum profiling by using PLC.

- Traceability and Batch data logging.

- Recipe-based operation

- Deviation control alarm system.

Pharmaceutical firms and R&D centers which are export oriented particularly appreciate such features.

Maintenance & Lifecycle Reliability

Consistent performance requires routine maintenance:

- Inspection of gaskets frequently.

- Vacuum pump oil replenishment at the right time.

- Condenser cleaning

- Instrument calibration on a regular basis.

A good Vacuum Tray Dryer has a long service life, low cost of operation and high reliability.

Why Choose Bionics Consortium?

In the case of Bionics Consortium, we are providing excellent laboratory and industrial drying solutions to customer demands.

Our Key Strengths:

- Long experience in drying technology in a vacuum.

- Finely-machined stainless steel construction.

- Custom-built solutions

- Competitive pricing

- Reliable after sale service.

Our attention is on quality, customization and long term performance in order to satisfy the different needs of the industry.

A Reliable Solution for Precision Drying

A vacuum tray dryer is a very important piece of equipment in any industry. It assists in maintaining quality of products, legal conformity, and expediency. It is able to dry at low temperatures and is important to pharmaceuticals, chemicals, food and research institutions.

We can provide high vacuum tray drying systems which will offer new and reliable solutions to drying of sensitive products based on solvents, preserving the product structure and complying with the strict industry regulations.

Today, call on our technical team to get the individual quote depending on your needs.