Laboratory Furnace is a high-precision heating instrument manufactured to create and maintain high temperatures in a controlled environment to conduct scientific research, experimentation, and industrial laboratory certifications. It is different from Laboratory furnaces as it is specifically built to provide consistent production of heat distribution, temperature regulation and repeatable outcomes unlike standard heating equipment, which is necessary in a laboratory where consistency and accuracy are paramount.

A high quality Laboratory Furnace Manufacturers in India is required to get reliable lab furnaces for academic research laboratories, as well as the industrial research and development departments, laboratory furnaces are crucial in material processing, thermal analysis and quality control.

Understanding the Role of a Laboratory Furnace

The use of a furnace in a laboratory doesn’t mean basic heating. A laboratory furnace helps in carrying out treatment of samples at a certain temperature for a set of periods without contamination or external intervention.

Common laboratory operation includes:

- Ashing and calcination

- Annealing and sintering

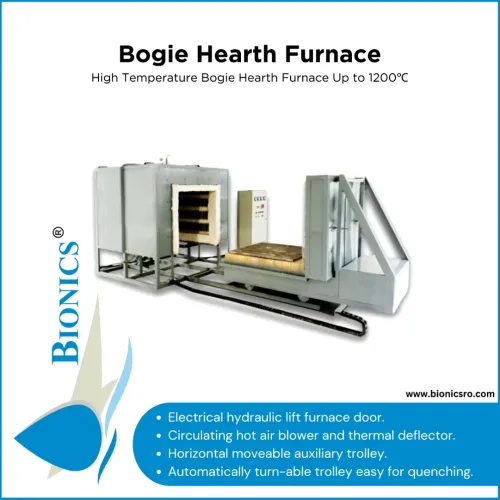

- Metallic and alloys heat treatment

- Melting and thermal stability test

Due to such challenging specifications, a laboratory heating furnace should be developed to be accurate, safe, and work throughout.

Temperature Range & Performance Expectations - Laboratory Furnace Suppliers in India

As a reliable Laboratory Furnace Suppliers in India, Bionics Consortium provides advanced high tech laboratory furnaces operating at a temperature between 500°C and 1800°C with more advanced versions beyond this and used in specialized research. These furnaces are commonly divided by temperature category:

- Small to medium furnaces used as routine tests

- High temperature furnace models used for material science and metallurgy

- Dedicated laboratory high temperature furnace systems used for extreme thermal application.

In case of laboratories that need high-performance due to their nature, industrial laboratory furnaces which offer greater capacity but still have lab-grade accuracy.

The most important Design Elements of importance to buyers.

Key Design Features That Matter to Buyers

The majority of laboratory furnaces have PID controllers with digital functions, and hence the temperature remains constant during the heating process. This is particularly so in long duration tests that may be compromised by fluctuation.

1. Uniform Heat Distribution

An efficient furnace chamber will make sure that all areas of the sample are evenly heated. This is one of the distinguishing qualities as compared to a typical heating unit and a pure high temperature laboratory box furnace.

2. Thermal Insulation & Safety

Modern laboratory furnaces come with advanced ceramic fiber insulation which helps in minimizing heat loss, improves energy efficiency and safeguard the external body. This is very important for furnace laboratory rooms where the safety of the operators and precise temperature control is important.

Different Types of Furnace Used in Laboratories – Best Laboratory Furnace Dealers in India

Bionics Consortium is Best Laboratory Furnace Dealers in India who has a wide range of laboratory furnaces which have different temperature ranges and helps in selecting the right furnace based on your application as different types of furnace are used in laboratories for different applications.

1. Laboratory Muffle Furnace

The most commonly used type is the laboratory muffle furnace. The chamber is in the shape of a box and its shape insulates the sample against any direct heating element that would cause contamination of the heating process.

Muffle furnace uses in laboratory applications include:

- Ash content analysis

- Chemical testing

- Processing of ceramics and glass

- The operations of heat treatment furnace

The laboratory muffle furnace specifications and laboratory muffle furnace price are usually compared by buyers in terms of chamber volume and maximum temperatures.

2. Laboratory Tube Furnace

The laboratory tube furnace has a cylindrical heating compartment, and is ideal when using small samples and experiments that need to have controlled flow of gases. These furnaces are usually employed in high level material studies as well as in testing of semiconductors.

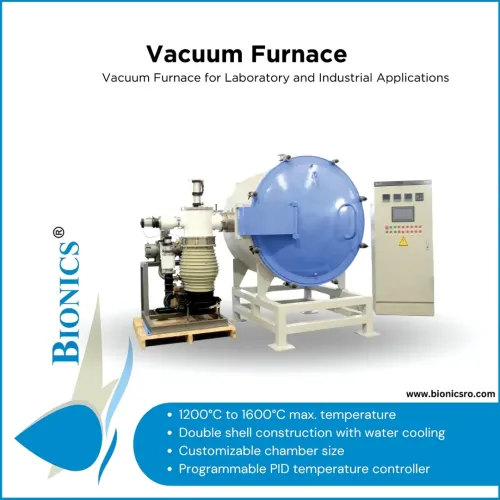

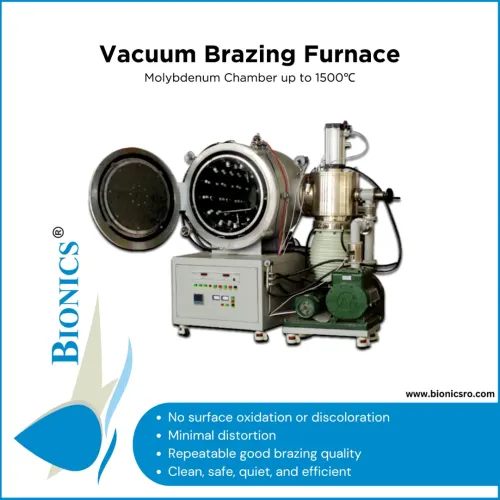

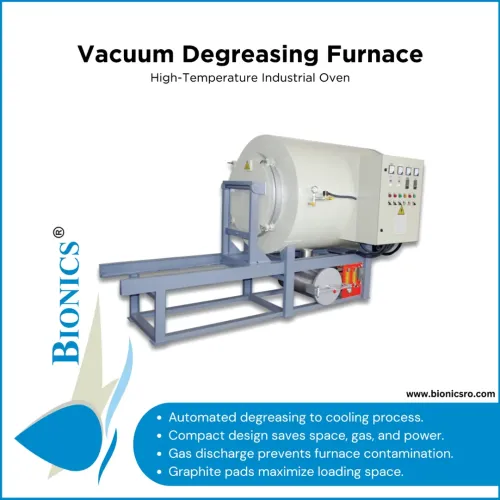

3. Laboratory Vacuum Furnace

A laboratory vacuum furnace enables heating under oxygen-free conditions and this prevents oxidation and contamination. Such systems are used in sensitive materials and fine metallurgy.

4. Laboratory Melting and Induction Furnaces

A laboratory melting furnace is used to melt metals and alloys in a controlled way whereas induction models exhibit high heating fast through electromagnetic energy. The main factors that buyers consider when determining the laboratory induction furnace price usually include power rating, crucible size as well as melting capacity.

Laboratory Furnace Applications Across Industries

Laboratory furnaces are highly applicable in many ways and this is the reason why they are widely utilized. Laboratory furnace uses are:

- Material Science: Sintering, ceramic testing, polymer research.

- Chemistry: Preparation of the sample, gravimetric analysis.

- Pharmaceuticals: Pharmacokinetic and pharmacodynamic studies.

- Metallurgy: Heat treatment, tempering and annealing.

- Electronics: Semiconductor testing and component testing.

- Education and Research: University and institutional laboratories.

All these applications are making the laboratory furnaces market in the world wider.

How to Choose the Right Laboratory Furnace Exporters in India

The correct choice of Laboratory Furnace Exporters in India, is vital in order to get heating furnace for laboratory use which is made with the clear understanding of the needs of its application:

- Sample size and capacity of the chambers

- Continuous or batch operation

- Air or space specification

- Accuracy and safety capabilities of control system

Knowing how to use laboratory furnace equipment safely is equally important including loading procedures, temperature programming, and cooling cycles.

Installation & Laboratory Setup Considerations

An efficiently designed furnace laboratory room enhances efficiency and safety. When installing them, adequate ventilation, electrical capacity and heat clearance should be factored in particularly when dealing with the installation of high temperature laboratory furnaces and industrial furnaces.

Operators Safety and Long Term Usage

A good industrial furnace or laboratory industrial furnace is meant to be used continuously and has to have minimum downtime. Other features like over-temperature protection, enclosures, and strong control electronics are vital in ensuring a steady performance in the long-term.

Market Trends & Buying Behavior

The lab furnace market is continuously expanding as a result of the greater level of R&D expenses and the development of the materials and the more critical quality requirements. Customers are no longer concerned with the initial price but with reliability, support in service and long-term operating costs.

This change has heightened the need of reliable laboratory furnace suppliers particularly those providing customization and technical services.

Get Customized Laboratory Furnace Solutions!

The laboratory furnace is a long-term investment, which has a direct influence on the accuracy of research, safety of operations, and reliability of the experiment. It is important to choose the type and supplier of the heat treatment furnace, high temperature laboratory furnace or an industrial laboratory furnace.

Since the knowledge of the furnace types, uses and performance criteria, the laboratories will be able to make sound decisions that facilitate both the current needs as well as research objectives in the future.