Lab centrifuges are vital pieces of lab equipment used to separate particles in a sedimentation process that is based on the density range, size, shape, and viscosity of the solution in which they are dispersed. It is manufactured and provided by best Laboratory Centrifuges Manufacturers in India and they are effective depending on the rotor speed and widely used in research and clinical applications, especially for chemistry, biochemistry, and molecular biology tests. Similarly, such multi-purpose instruments have been useful in a variety of processes like organelle separation, purification, or isolation of cells, organelles, as well as cellular structures. Besides, these are also essential in solving extended issues related to nucleic acid interaction or separation with proteins or viruses, followed by their further analysis.

Laboratory centrifuges have been known since time immemorial; this was evidenced by the milk cream venting invention in the 1800s, although many other inventions followed it. However, their purpose began to change rapidly after the development of biochemistry that required devices with greater centrifugal forces. This gave birth to commercial laboratory centrifuges, which can be found on the market today.

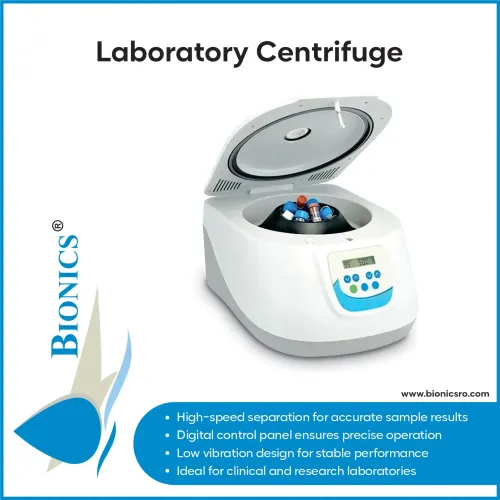

Top Laboratory Centrifuges Suppliers in India

Bionics Consortium is the Laboratory Centrifuges Suppliers in India, when talking about laboratory centrifuge products. We supply laboratory centrifuge equipment throughout India. Furthermore, we export this product to Asian nations plus Africa, along with Middle Eastern ones there too. One thing you should know is that a laboratory centrifuge is an important piece of equipment used in labs.

What is meant by Laboratory Centrifuge?

Centrifuge refers to a laboratory instrument employed to distinguish between two samples whose densities differ slightly or separate samples having nearly equal densities through spinning them around a defined axis. These are motorized devices that ensure rotating motion for the samples.

A centrifuge is used to separate heterogeneous mixtures into several parts, such as liquids, solids, and gases, depending on their density differences. These are typically applied in the process of sorting out red blood cells and other related blood units from whole human blood. In this case, the latter is a crucial part of centrifugation that is based on the sedimentation principle, where particles in suspension must settle within the medium while being in contact with a barrier. The centrifugal acceleration separates such particles, whereby the lowest solution density floats while the denser solution settles at the bottommost section of a container. Consequently, when there is an increase in both particle interaction and mean free path of particles between solution and solvent (higher density difference), higher particle speeds occur; conversely, if there is no or low density difference, then in this situation centrifugal force will be exerted by the centrifuge to help separate these particles.

How do centrifuges work – Trusted Laboratory Centrifuge Dealers in India

A Trusted Laboratory Centrifuge Dealers in India offers laboratory centrifuge for labs that collects a liquid sample in a container and rotates it at very high speed by spinning the rotor driven by an electric motor. The speed is called RCF, relative centrifugal force, and can be described as gravity multiplied by x. This would increase the rate of settling down of the solids since they are pushed outwards towards the sidewalls of the container by centrifugal force. In addition to their sizes, laboratory centrifuges are made in such a way that one can find different types and kinds of rotors used depending on what type of tasks they should perform. This means that even the size and type of sample tubes determine what these units can do best. They may be suited to most solvents; however, glass tubes are more expensive than others with a longer life-span but tend to hold water better. But if you have large samples, instead of using tubes, you should use centrifugation bottles.

Main Features of a Centrifuge:

- The chamber has excellent cleaning ability due to its stainless steel.

- Motor having brushless induction and variable frequency drive.

- This device contains a digital display microprocessor controller with a lunch plan for pupils with a balanced diet from different grades.

- This feature enables the system to maintain constant output when there is voltage fluctuation.

- Smooth start, low sample temperature rise No interruption during fault detection Inverter output is adjusted via a 7-segment LED display panel.

- The count-down timer is digitally displayed and will continue operation endlessly.

- Safety lock: locked lid ensures safe operation without opening while running this equipment.

- Error message indicating balancing fault mode during beginning up stoppage Braking facility (dynamic)

- Rapid braking system: this helps in reducing train speeds quickly.

- Door hinge construction where gas mechanism prevents door dropping

- Emergency button for unlocking lid

- Recall of the last set parameter (if you perform one and the same test on a regular basis)

- Huge selection of rotors and reduction adapters

Different Types of Centrifuge Rotors

In addition to the centrifuge type, the centrifuge rotor should also be taken into account when deciding what it is going to be and how much it will cost.

- Swinging bucket rotor: Buckets of this impeller-motor initially are perpendicular to the rotation axis, and during acceleration they swing parallelly. The tube with its contents is maintained in a position parallel to the centrifugal force direction but perpendicularly relative to the centrifuge rotary axis.

- Fixed-angle rotor: Sample types for such a rotor are positioned at an angle ranging from 14° to 40°. According to the relative centrifugal force, particles must be pushed outwards so that their impact will occur on the outer wall of the centrifuge tube.

- Continuous-flow rotor: The higher localized concentration area than that present in the surrounding medium is formed. Further away from the center, precipitates are collected more compactly.

- Rotors like continuous flow or drum rotors are much more restrictive than these that require special disciplines such as fixed-angle or swinging bucket rotors. However, there is a time when one understands the significance of having a continuum of patients, customers, and so forth.

- This is seen as a convenient feature for working efficiently at high centrifugal forces, filling and filtering many centrifuge test tubes, or processing large amounts of material without having to switch off and on the rotor over and over again.

- Flow rotor is more applicable in samples such as cell and algae harvests, mitochondria, large viruses, bacteria, and tissue homogenates.

Difference between Leasing and Buying a Centrifuge

The cost of purchasing a centrifuge can be quite high, depending on its capacity and the quantity purchased. Nonetheless, laboratory centrifuges are much less costly and can be found almost everywhere in the market. Bench-top laboratory centrifuges may not be ideal if budgetary constraints are an issue. However, leasing lab equipment from companies like Exceeder could offer cost-effective alternatives by lessening financial responsibilities, including maintenance and repairs in the lease agreements. As such, at the end of the contract period, they are normally able to replace their items, unlike with assets that they own. This way, laboratories have access to high-quality equipment tailored to their specific requirements.

Important features to consider Before Buying Laboratory Centrifuges :

- Brushless motor that requires no maintenance, reducing overall maintenance costs.

- Specially improved safety features include a safety lid lock and design, systems for detecting imbalances, rotor auto identification, and other factors, such as over-speed and over-temperature protection.

- A single-chip microcomputer control system that can show set and actual data at the same time

- The emergency switch feature allows the lid to be opened by hand if it fails mechanically or in the absence of a power supply.

- Automatic conversion of parameters: ratio of reversible change in frequency from RCF to RPM and vice versa; reversible change of temperature from Celsius to Fahrenheit and vice versa

- Some parameters can be adjusted while operations are being carried out to increase your work effectiveness.

- Plenty of accessories have been produced that can meet a wide variety of applications.

- The awning-type outer surface, which can be easily cleaned, is protected with Isocide to provide 99.9% of bacteria present on the surface die within 24 hours.

- Integrated design of the cutting chamber in the interior.

- Sub-zero to warm temperatures (-20°C–+40°C) for refrigeration models.

- Fast-acting pre-cooling button to reduce chamber temperature before the run starts.

- Environmentally friendly CFC- and HCFC-free refrigerant

Uses of Laboratory Centrifuges – Reliable Laboratory Centrifuge Exporters in India

There are various types of centrifuges available in the laboratory, sourced by Laboratory Centrifuge Exporters in India each of which is used primarily for analysis and separation based on sedimentation principles. This general operating principle is the basis of all centrifuge types.

- Micro-centrifuge: It has a compact design, hence occupies little space compared to other models. This kind can hold small tubes containing around 2 ml used for pelleting proteins or micro-filtrating similar aqueous samples on a small scale, as commonly applied in molecular biology.

- Refrigerated Centrifuge (RCF): On some occasions, preservation involves cooling samples within certain temperature limits. While maintaining the temperature setting, operators should set higher maximum speed settings.

Generally, the frequently encountered temperature range is from -20 to 40 degrees Celsius, while the maximum spin rates are up to 30,000 revolutions per minute thus producing forces up to 65,000 g. The refrigerating centrifuges can carry one of these - fixed-angle rotors or swinging-bucket rotors or a combination rotors - at most.

- Ultracentrifuge: Ultracentrifugation enables separation of particles like proteins from nucleic acids having highly similar properties. High-speed refrigerated centrifuges generate forces greater than the force of gravity. Two types of ultracentrifugation exist:

- Preparative Ultracentrifuge: Macromolecules and lipoprotein fractions from plasma, for example, can be separated using this ultracentrifuge that can generate forces of up to 600,000 g. Preparative ultracentrifuges are provided in different rotor capacities.

- Analytical Ultracentrifuge: An optical detection system in this ultracentrifuge allows real-time observation of the sedimentation process. This can generate centrifugal forces of up to 500,000 g. Light absorption, Schlieren, or even Rayleigh interferometric systems may be part of an optical detection system.

- PRP/PRF Centrifuge: Dentistry, aesthetic clinics, and hair transplant centers normally use this centrifuge, which separates patients’s plasma from blood.

- Blood Centrifuge: Used for recovery and pain management purposes in various medical fields for separating plasma.

Important Considerations When Buying Laboratory Centrifuges

- Brushless Motors: Maintenance-free motors that do not use brushes lower the overall cost. Advanced safety features: priority safety lid lock, imbalance detection system, rotor automatic identification, over speed protection and over temperature protection.

- Control Systems: A single-chip microcomputer control system enables simultaneous display of set and actual data.

- Emergency Switch: Lid release switch used manually during mechanical failure or power cuts

- Automatic Parameter Conversion: Easy reversible RCF/RPM and Celsius/Fahrenheit temperature conversions

- Adjustable Parameters: Some types of centrifuges allow for performance improvement through parameter adjustments during operation.

- Surface Design: Those with awning-type surfaces are easy to clean, with 99.9% bacteria killed within 24 hours on contact.

- Refrigeration Models: Pre-cooling buttons are available in refrigeration models operating at temperatures between -20°C and +40°C to cool the chamber quickly before beginning a run.

- Environmentally friendly refrigerants: opt for centrifuges employing CFC- and HCFC-free refrigerants.

Applications of Laboratory Centrifuges

These are the applications of laboratory centrifuges:

- Biochemistry: The centrifuge is a part of the blood-cell-separating apparatus that is also used for sedimenting protein precipitates in DNA preparation, RNA, or cell culture samples.

- Chemistry: It is used to separate chemical and biochemical solutions that have different molecular masses. These machines can be used for biology tasks such as sedimentation, molecular cloning, and purification of proteins.

- Molecular Biology: The instrument is employed in the isolation of proteins and nucleic acids from a mixture.

- Biotechnology: The centrifuge is a part of the system for the production of industrial proteins, lipids, and nucleic acids.

Laboratory centrifuges are essential scientific research tools that have the flexibility to be used in a wide variety of different ways. Along with being instrumental in the separation, they are also used for the purification of different compounds through biochemistry, chemistry, molecular biology, and biotechnology processes. In order to get reliable results in the lab, it is very important to have the correct micro centrifuge taking into account factors such as rotor type, control systems, safety features, and so on.